Table of Contents:

1. Introduction

In the realm of alcohol strength determination, the choice of methodology is a critical decision for producers and laboratories alike. This article delves into the nuanced world of oenological distillation, exploring scenarios where this traditional practice surpasses other laboratory instruments in determining Alcohol Strength by Volume (ABV).

2. Historical Perspective

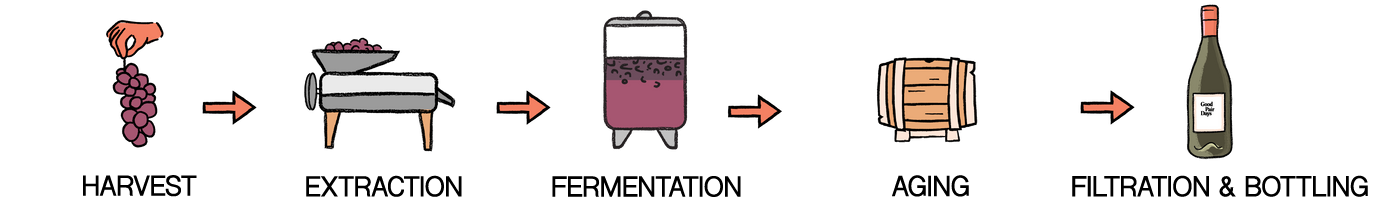

Oenological distillation, deeply rooted in the history of winemaking and spirits production, has been a cornerstone of alcohol analysis for centuries. Its legacy is intertwined with the evolution of beverage craftsmanship, and its continued relevance highlights the enduring reliability of this method. In the 16th and 17th centuries, distillation was increasingly used as an analytical tool to measure alcohol content in various liquids, including wines. During the 19th century, with the advancement of analytical chemistry, there was a greater standardization of distillation techniques and wine analysis. Regulation in the wine industry and the need for precise information on products led to a more systematic use of distillation to measure alcohol content. In the 20th century, with the progress of technology and analytical methodologies, new techniques for measuring alcohol content, such as spectroscopy and chromatography, were introduced. However, distillation continues to be a common and standard practice in determining alcohol content in wines, especially those destined to become spirits or liqueurs.

3. Regulatory Compliance

The importance of adhering to regulatory standards cannot be overstated. Oenological distillation emerges as a stalwart ally in meeting legal requirements for precise measurement and reporting of alcohol content. Recognized and approved by organizations like the OIV (International Organization of Vine and Wine), distillation ensures that reported alcohol levels align seamlessly with regulatory benchmarks.

4. Precision and Accuracy in Distillation

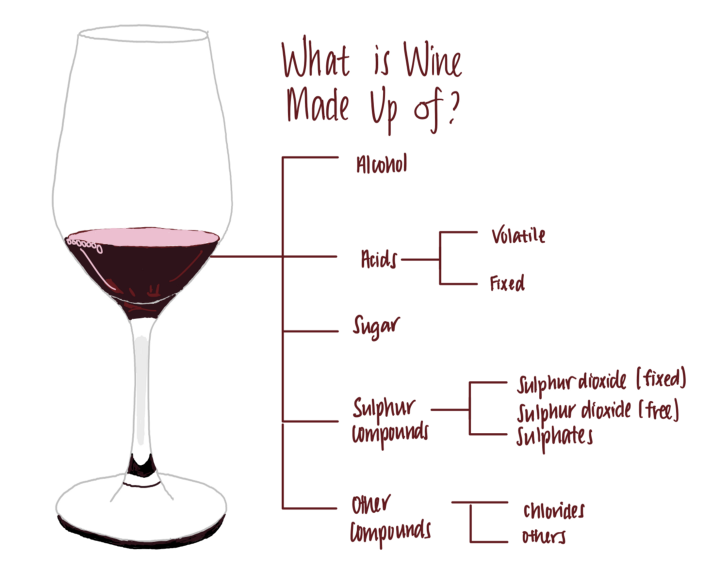

One of the distinctive strengths of oenological distillation lies in its precision and accuracy. When the utmost precision is required, especially in comparison to alternative methods like density measurements or refractometry, distillation proves its mettle. It stands as a reliable method that provides results with minimal limitations, ensuring the integrity of alcohol strength determinations.

5. Validation of Analytical Methods

Beyond being a standalone methodology, oenological distillation serves as a validation tool for other analytical approaches. In instances where doubts linger regarding the accuracy or reliability of alternative methods, the comparative analysis facilitated by distillation becomes a crucial step in the validation process. In the ever-advancing landscape of analytical methodologies, the role of oenological distillation as a validation tool takes center stage, providing a critical lens through which the reliability of alternative analytical methods can be confirmed.

5.1 Distillation as a Benchmark for Accuracy

Oenological distillation, with its historical grounding and recognized accuracy, serves as a benchmark against which other analytical methods can be measured. When doubts arise about the precision of an alternative method in measuring alcohol content, the comparative analysis facilitated by distillation becomes a litmus test for accuracy.

5.2 Confirming Reliability through Distillation

The validation journey involves subjecting the alternative method to scrutiny, comparing its results with those obtained through distillation. Distillation, known for its precision and reliability, becomes the standard of truth against which the accuracy of the alternative method is assessed. This process instills confidence in the reliability of the chosen analytical approach.

5.3 Integration of Validation into Quality Assurance

The validation of analytical methods is not merely a technical exercise; it is a strategic integration into the broader framework of quality assurance. By leveraging the reliability of oenological distillation, producers and laboratories establish a robust foundation for ensuring the consistency and accuracy of their analytical processes.

6. Navigating Non-standard Samples

Not all beverage samples are created equal. Wines with high sugar content, residual carbon dioxide, or complex matrices, along with other challenging scenarios such as those presented by dark beers, can be a testing ground for analytical techniques. Oenological distillation steps up as the method of choice for such non-standard samples, ensuring accuracy and reliability in the determination of ABV.

7. Versatility

One Distiller, Many Products: The versatility of oenological distillers is a key attribute that sets them apart. With just one piece of equipment, producers and laboratories can navigate the intricacies of different beverages—varying in colors, densities, and alcohol content. This adaptability proves especially advantageous for third-party laboratories and bottling services, streamlining their analytical processes.

8. Integrating Technology with Tradition

While technological advancements have introduced innovative methodologies, the marriage of technology with traditional practices remains a hallmark of the beverage industry. Oenological distillers, though rooted in history, have evolved to integrate modern features that enhance efficiency without compromising the authenticity of results.

9. Conclusion

In the evolving landscape of alcohol strength determination, oenological distillation stands as a timeless and reliable method. Whether for regulatory compliance, precision and accuracy, validation of methods, navigating non-standard samples, or achieving versatility with a single piece of equipment, distillation continues to play a pivotal role in the beverage industry. As we conclude this exploration, it becomes evident that the choice between oenological distillation and other laboratory instruments is not merely a technical decision but a strategic one. The integration of tradition with technological advancements exemplifies the industry's commitment to both heritage and progress, ensuring that each drop of beverage analyzed reflects the rich tapestry of craftsmanship and innovation.SDEE: Automatic Oenological Lab Distiller

Digital Laboratory Equipment compliant with the OIV official method (OIV regulations) for the measurement of alcoholic strength by volume (ABV testing) and volatile acidity - where applicable - in wines, musts, beers, distilled spirits, liquors, as well as foods containing alcohol in general.